Law firm efficiency

Optimising processes to boost profits

The law firm RP Richter & Partner has given their clients advice on taxes, accounting and legal affairs since 2001. Richter & Partner offers competence and quality comparable to the biggest auditing companies in the industry, and combine this with the personal connection, productive atmosphere, individuality and intimacy of a manageably sized office. Currently, the law firm employs more than 200 people in its Munich, Frankfurt and Stuttgart locations.

Initial Situation

RP Richter & Partner wants to tackle price pressures and improve profitability. They especially think that their standard compliance services (annual account statements, accounting, tax declaration) can be made more profitable and efficient. Process improvements should be made especially in the fields of order processing (prioritisation of tasks, work interruptions and parallel processing), document processing (to mitigate incomplete document delivery by clients), and during the review of reports (to address delays and quality-control issues).

Challenge

In order to make their target processes more consistent and efficient, Schoen + Company investigated the structures (different IT-systems for office management, public relations and document processing) and procedures for single compliance areas.

Additionally, the law firm wanted to revisit their outsourcing model for compliance services, and introduce a digital client file. Working with external consultants allowed to help them keep the project’s time burden on their employees to a minimum and keep it from interfering with regular company operations.

Approach

The approach can be divided into the following steps:

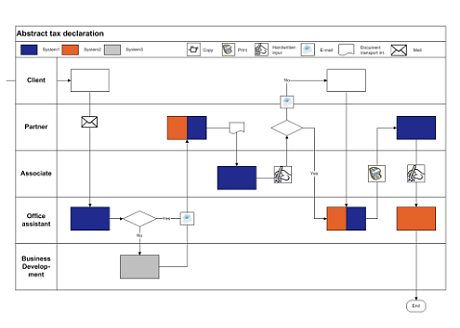

- Analysis of the actual processes: interdisciplinary workshops with the specialised fields of compliance and their administrators

- Analysis of quantity structure: number and duration of processes, gross/net view, sub-process structure, distribution of staff hours

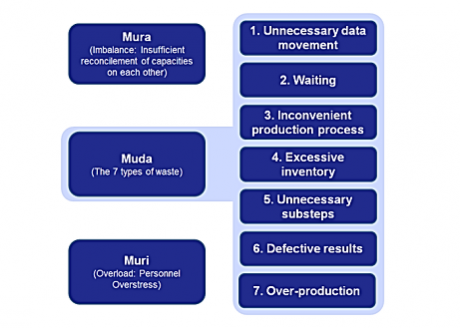

- Identifying wasteful areas: systematic identification of wasteful areas with the 3 Mu and 7 Muda

- Determining target processes: workshops on the conceptual design of new target processes and benchmarking against reference projects

- Calculating savings potential: quantification of different profit-boosters (e.g. process optimisation, systems, overtime hours, capacity utilisation and team configuration)

- Implementation assessment: establishing and categorising implementation assessment criteria – for the process, system and controlling levels – into short-, medium-, and long-term implementation target-groups.

Results

The following results were obtained at each stage of analysis:

- Created visualisations illustrating the actual processes, including times, participants, costs and systems

- Quantitative transparency of activities

- Systematic plans for improvement in over 80 waste areas

- Consistently designed and efficient target processes

- Quantifiable savings plans

- Plan for implementing solutions

Process optimisations were identified that can yield time-savings of approximately 13 %, reducing first overtime hours and then the expense ratio. Additional profitability boosters make cost savings of up to 45 % possible.